Casting your own shapes affords you the opportunity to carve and cut into the greenware.

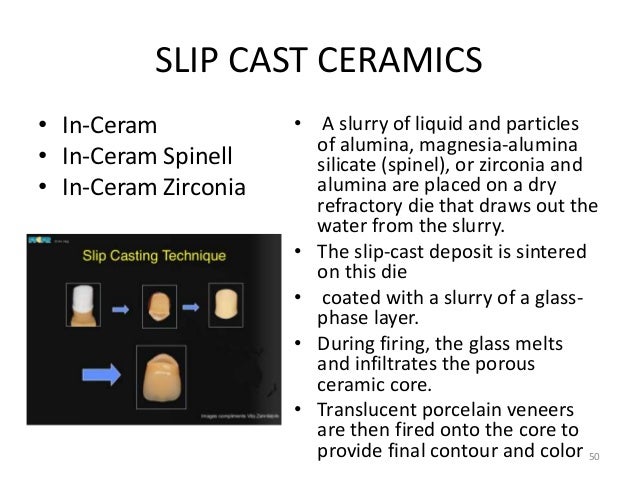

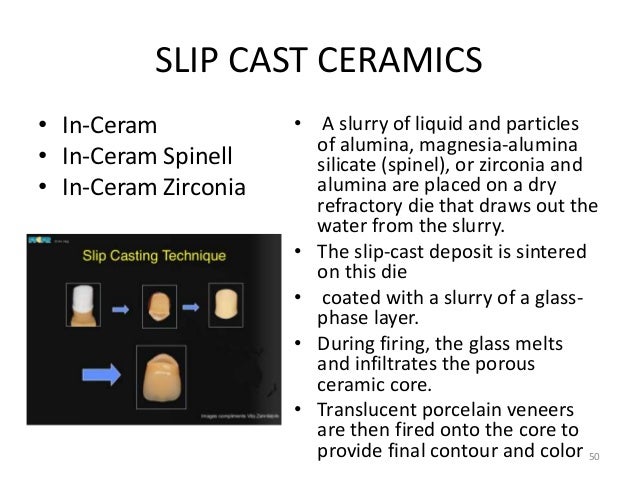

Slip casting ceramics dental.

For a tutorial on how to make a plaster mold please refer to the plaster mold making tutorial for more information.

What is the slip casting of ceramics.

Porcelain a ceramic which is often used in cooking and dishware made up of a mixture of clays.

Bags that require mixing with water and a deflocculant such as soda ash sodium silicate darvan 7 or darvan 811.

Casting slips are pre made ready to use for pouring and making casts in plaster molds.

The thickness of this skin is proportional to the time for which it is allowed to form.

Slip casting molds by mayco.

Slip a liquid suspension of ceramic particles in water.

Pröbster l 1 diehl j.

We also have dry mix casting slips available in 50 lb.

Slip cast all ceramic materials introduced in dentistry in the 1990s condensation of a porcelain slip on a refractory die aqueous slurry containing fine ceramic particles.

Due to the porosity of the gypsum capillary forces draw the suspension medium water into the mold.

This tutorial is demonstrating how to slip cast porcelain in an already existing plaster mold easily and efficiently.

This happens because the mold absorbs the water from the slip through its pores collecting the ceramic particles against the mold.

Slip casting alumina ceramics for crown and bridge restorations.

Slip casting can be useful for making multiples of one object and to make casts that are hollow on the inside.

2 2 slip casting pressure slip casting a more classic shaping route known from traditional ceramics and porcelain products is slip casting.

Slip casting is the process of filling the molds with slip which is the liquid clay allowing it to solidify and after a while forming a layer called the cast inside of the mold s walls.

Slip casting a method used to make complex shaped ceramics without having to melt them.

Slipcasting or slip casting is a ceramic forming technique for pottery and other ceramics especially for shapes not easily made on a wheel.

In slipcasting a liquid clay body slip usually mixed in a blunger is poured into plaster moulds and allowed to form a layer the cast on the inside walls of the mould.

In slip casting the porosity of the plaster mould absorbs the water in the ceramic slurry taking the shape of the mould and creating the cake.

This wet shaping technology starts from aqueous slurries which are poured into a plaster mold.

Here s a document you can download that covers many of the basics.

Casting molds have been an integral tool for ceramists for decades.

Liquid casting slips are available in low fire midrange stoneware high fire stoneware and porcelain.